Products

CBL-800 Bi-metallic composite bearing material consists of steel backing with lead bronze or lead-free copper alloy (CuPb10Sn10、CuPb6Sn6Zn3、CuPb24Sn4、CuPb30、AlSn20Cu)lining, bearing material for oil/grease lubricated applications. The copper alloy forms a continuously frame for thermal conductivity. These bearing structures are with high load capacity and good fatigue property. Higher tolerance can be achieved after re-machined from the customers. Lead-free bronze lining bearing material conforms to the European RoHS directive.

Application

Angineering machine: underpan, thrust wheel, Towing wheel, Steering knuckle,tension pulley...

Automotive:trunnion shaft, connecting rod, valve rocker, camshaft, gear box, internal-combustion engine,

And Plunger pump friction plate, gear pump friction plate...

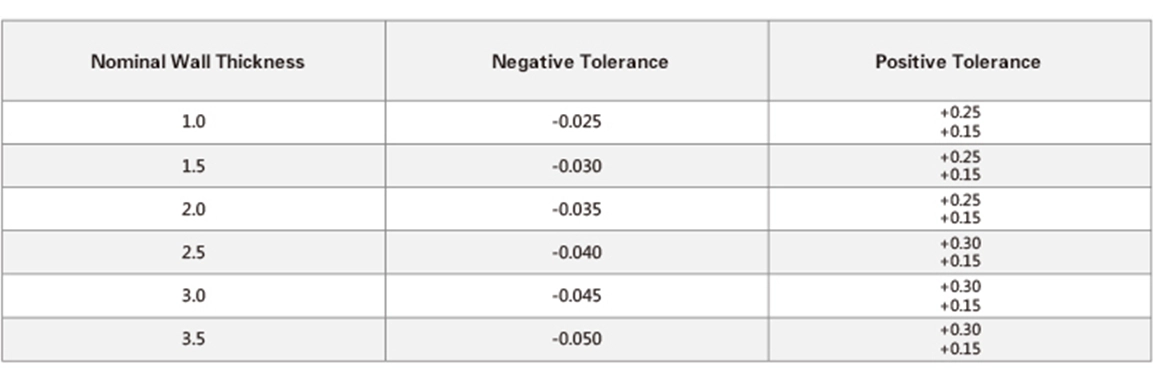

Tolerance of Wall Thickness

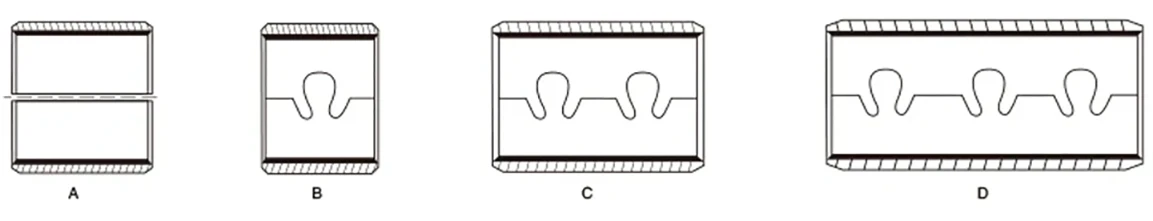

Oil Groove

Buckle Form

CBL-800 Tech. Deta

|

The use of parameters |

|

|

|

|

|

|---|---|---|---|---|---|

|

Parameters |

CBL-800 |

CBL-801 |

CBL-802 |

CBL-803 |

CBL-08G |

|

Material type |

CuPb10Sn10/ CuSn6Zn6Pb3 |

CuPb24Sn4 |

CuPb30 |

AlSn20Cu |

CuPb10Sn10+Graphite |

|

Hardmess of bronze alloy |

70~100HB |

45~70HB |

30~45HB |

30~40HB |

60~90HB |

|

Max. dynamic Load |

65N/mm² |

38N/mm² |

25N/mm² |

30N/mm² |

90N/mm² |

|

Sapphire" fatigue class |

125 |

115 |

105 |

105 |

- |

|

Friction coefficient(oil) |

0.06~0.14 |

0.06~0.16 |

0.08~0.16 |

0.08~0.17 |

<0.08 |

|

PV limit(Grease) |

2.8N/mm².M/s |

2.8N/mm².M/s |

2.5N/mm².M/s |

- |

2.8N/mm².M/s |

|

PV limit(Oil) |

10N/mm².M/s |

10N/mm²2.M/s |

8N/mm².M/s |

6N/mm².M/s |

10N/mm².M/s |

|

Max. temperature |

260℃ |

200℃ |

170℃ |

150℃ |

200℃ |

|

Load limit |

150N/mm² |

130N/mm² |

120N/mm² |

100N/mm² |

90N/mm² |

|

Speed limit v max. |

5m/s |

10m/s |

15m/s |

25m/s |

5m/s |

|

Hardness of mating surface |

53 HRC |

50 HRC |

270 HB |

250 HB |

53 HRC |

|

Tensile strength |

150N/mm² |

150N/mm² |

200N/mm² |

200N/mm² |

185N/mm² |