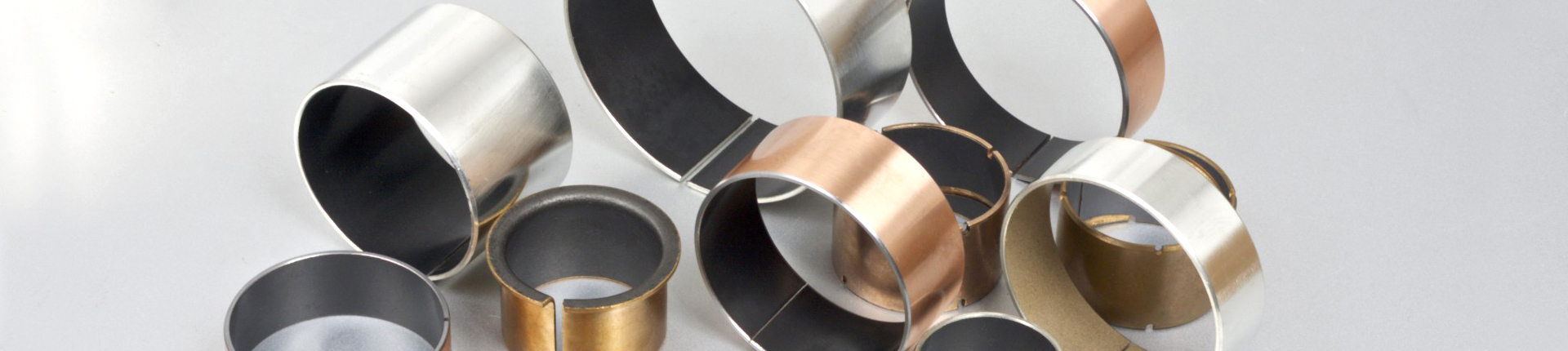

CBL Solid-lubricating And Maintenance-free Sliding Bearings

CBL SELIDING BEARING

Solid-lubricating and Maintenance-free Sliding Bearings

CBL-10 Self-lubricating Bearings

Solid-lubricating and Maintenance-free Sliding Bearings

CBL-20 Marginal Lubrication Bearings

Solid-lubricating and Maintenance-free Sliding Bearings

<

>

Manufacturing Material

1 Metal materials, such as bearing alloy, bronze, aluminum alloy, zinc alloy etc.

Bearing alloy bearing alloy: also known as white alloy, mainly is the alloy of tin, lead, antimony or other metal, because of its wear-resistant, high plasticity, good running performance, good thermal conductivity and anti adhesive and adsorption resistance and oil well, it is suitable for heavy load, high speed condition, Zhou Chenghe gold intensity is small, the price is more expensive, the use must be cast in bronze, steel or cast iron bearing on the formation of coating, thinner.

2 Porous metal materials (powder metallurgy)

Porous metal materials: porous metal is a kind of powder material, it has a porous structure, if the dip in the lubricating oil, the lubricating oil filled pores, into the bearing with self lubrication performance. Porous metal material toughness is small, only to no impact load and speed, stable in small case.

3 Non metallic materials

Plastic: plastic bearing bearings are commonly used phenolic plastics, nylon, polytetrafluoroethylene, plastic bearings have high compressive strength and wear resistance, used oil and water lubrication, also has the self lubrication properties, but poor thermal conductivity.

Sliding bearing at work because of shaft and bearing contact will cause friction, causing the surface heating, wear even "killed", so in the design of bearing, should choose the antifriction good sliding bearing material manufacturing bush, suitable lubricant and the supply method suitable for thick film lubrication, so as to improve the bearing structure.

< Previous

Next >

Link name:Bearing Suppliner